Surgical tool maintenance involves cleaning, sterilizing, and storing surgical instruments. These measures are crucial for increasing surgical tools’ lifespan, effectiveness, and safety.

Maintaining surgical instruments is a standardized process, and established guidelines and techniques precisely regulate the hows behind it. This article explores evidence-based practices for maintaining surgical instruments, covering cleaning protocols, sterilization techniques and proper storage.

Importance and basics of surgical tool maintenance

Fundamental principles

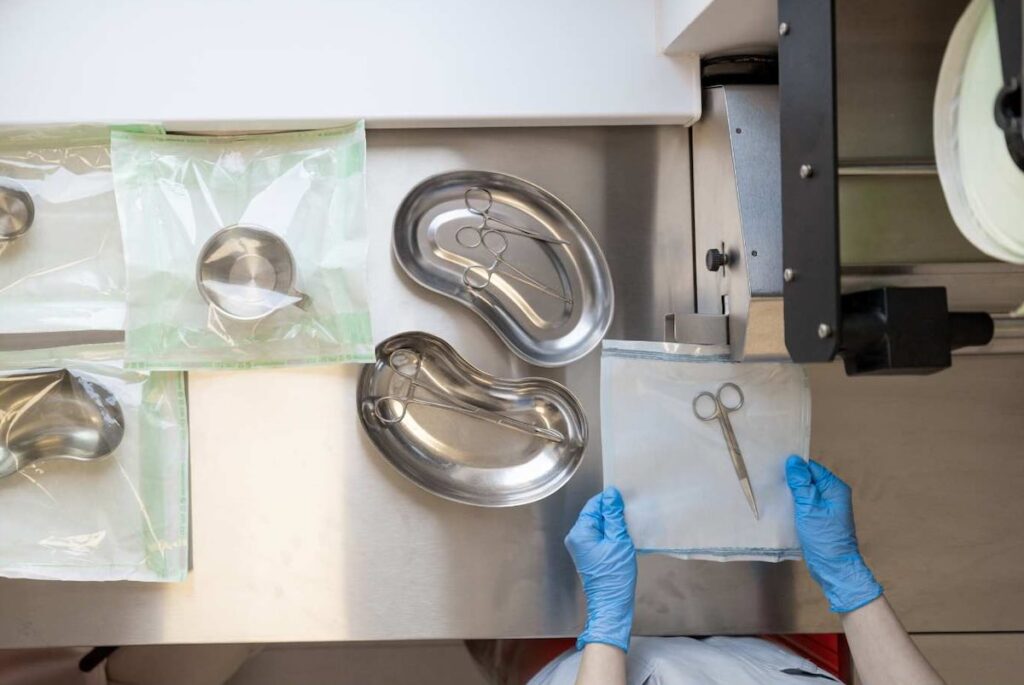

Cleaning, sterilization, and proper storage are the three main aspects of maintaining surgical tools. Each step is essential in preserving the overall integrity of the instruments and the surgical procedure.

Cleaning is the removal debris and organic matter from surgical instruments using physical and chemical means, such as water and detergent. It is the first step of tool maintenance that precedes sterilization. Sterilization involves techniques like steam sterilization that render surgical instruments free from all forms of microorganisms, including bacteria, viruses, fungi and spores.

Cleaned and sterilized surgical instruments are stored in controlled environments, such as closed cabinets or covered carts, to maintain their hygiene and prevent damage or unnecessary handling.

Safety implications

Properly maintaining surgical tools helps prevent surgical site infections (SSI), thus ensuring patient safety. SSIs can lead to increased morbidity, extended hospital stays, and, in severe cases, mortality. The risk of infections from an adequately sterilized instrument in the surgery room is essentially zero. However, any mishandling of surgical tools can lead to their contamination.

Functionality and longevity

Regular maintenance and proper handling prolong the lifespan of surgical instruments by at least 10 years, according to the Association of periOperative Registered Nurses (AORN) Journal. Competent care also optimizes the functionality and efficiency of surgical tools. These benefits translate to considerable cost savings for healthcare facilities and improved reliability during surgery.

Cleaning protocols for surgical instruments

Surgical tools have manufacturer-validated cleaning and decontamination instructions for use. These are approved by governing agencies, such as AORN and the Food and Drug Administration (FDA) in the United States. According to the cleaning and care guidelines (PDF) published in AORN Journal, surgical team members must comply with the instructions for use without exception. These instructions apply to any instrument, whether new, repaired, refurbished, or loaned, and determine the processes of cleaning, decontamination, sterilization, or high-level disinfection.

The cleaning of surgical tools typically begins with a pre-cleaning stage in which the tools are dried and prepared for cleaning using instrument transport gels. The second step involves manual cleaning in a three-bay sink configuration. Finally, surgical tools undergo automated cleaning methods, such as ultrasonic cleaning systems and washers or disinfectors like enzymatic detergents.

The abovementioned clearing and care guidelines also recommend inspecting surgical instruments for alignment and functionality, including checking for damage or defects. Fragile instruments, such as intraocular ophthalmic instruments, demand special caution in this regard.

Every cleaning and disinfection process must be documented; the documentation should specify the:

- Date and time of the cleaning procedure

- Instrument identification

- Cleaning method and verification

- Mechanical washer identification

- Name of the person performing the cleaning procedure

- Cleaning agent lot numbers

- Defective equipment disposition

- Cleaning equipment maintenance records

Sterilization techniques for optimal safety

Surgical sterilization is performed preoperatively to optimize instrument performance and improve their safety. Before sterilization, surgical instruments are air-dried or dried by using compressed air.

There are many techniques for sterilizing surgical tools. Autoclaving (steam sterilization) is a popular, effective, and safe method that uses pressurized steam to eliminate microbes. It’s widely used for metal instruments, glassware, and heat-resistant devices. Autoclaving is regulated by comprehensive guidelines, such as the Centers for Disease Control and Prevention (CDC) guidelines or ANSI/AAMI ST79 guide.

Ethylene oxide gas sterilization is another common method, particularly for heat-sensitive instruments. Despite its popularity, it is time-consuming, expensive, and poses potential health risks. Additional sterilization techniques include hydrogen peroxide gas plasma, liquid chemical sterilization (using materials like peracetic acid or glutaraldehyde), dry heat, and ozone sterilization. Each method has advantages and limitations.

Less commonly used sterilization techniques include microwaves, infrared radiation, ionizing radiation, and ultraviolet light. These procedures are not FDA-approved because of concerns regarding their effectiveness, safety, and costs.

Proper storage and handling of surgical tools

Sterilized surgical tools should be stored in a clean and dry environment. Sterile tip protectors, caps, or cases can help to maintain instrument fitness and avoid possible damage or contamination during handling.

Autoclaved packs or wrapped trays are common means of storing instruments. The shelf life of sterilized items depends on the packaging material and storage conditions. For small metal instruments, autoclaved packages in wrapped linen or wrapped plastic-paper combinations can be stored safely for at least 96 weeks.

According to the Joint Commission, the surgical tool storage area should have controlled temperature and humidity. This control begins with building code regulations, which include ventilator equipment requirements. The relative humidity within the storage area should not exceed 60%, while the temperature should fall into a 22–26°C (72–78°F) range.

Use and disposal of single-use surgical instruments

Single-use or disposable instruments are made of materials such as highly durable plastic, rather than metal, and are discarded after use. Examples include stents, orthopedic implants, catheters, needles, and scalpels, as well as our Yasui koplight™ cordless retractor. These tools may have limited heat tolerance and, as such, cannot be reliably cleaned or sterilized. This property promotes their safety and cost-effectiveness.

The use of single-use instruments has increased in the past decades due to a fear of transmitting prion diseases and infections associated with contaminated reusable instruments.

Medical facilities must adhere to regulations regarding using and disposing of single-use devices, such as the Medical Devices Directive (PDF) in Ireland. According to this directive and similar guidelines, single-use tools apply to a single patient or surgical procedure. However, when a surgical instrument marked by the manufacturer as single-use is reprocessed, the party responsible for placing the reprocessed device on the market or using it assumes legal responsibility.

Regular inspections and maintenance checks

Regular inspections and checks of surgical tools ensure that they’re in optimal working condition and promote surgical safety and efficiency. Inspections help identify eventual dullness, misalignment, or damage, thus preventing potential uses of defective tools. Comprehensive guidelines, such as these ones (PDF) from AORN Journal, are available to precisely determine the standards of surgical tool inspection.

Medical staff should inspect all surgical instruments for debris, staining, corrosion, pitting, nicks, or burrs. Instead of paper, a surgical gauze or fabric can help detect blade sharpness problems. They should also check cutting and grasping instruments for even alignment when they are closed, functional opening and closing mechanisms, adequate tension, and secure grip and handling ability. Other instruments might also require screw function checks, lens clarity, cord function, and insulation integrity.

Troubleshooting common issues with surgical tools

Surgical instruments not undergoing maintenance checks may malfunction intraoperatively, leading to prolonged or failed procedures and patient harm. There are issues commonly affecting surgical tools, which regular maintenance can prevent.

Corrosion

Corrosion is a frequent issue that compromises the integrity of surgical instruments. It results from the adhesion of chlorides originating from blood or other bodily fluids retained on the instruments during surgery. The chlorides remain present on the tools with improper cleaning, inadequate drying, or inadequate inspections.

Malfunction

Instrument malfunction or failure caused by mechanical issues can occur due to instrument degradation or improper handling. According to a study analyzing equipment failure in the operating room, needle holders with a compromised grip were the most common issue, accounting for 67% of surgical instrument issues. Slipping tissue forceps and blunt dissecting scissors were the next most common issues.

Surface damage

Scratches or pitting on instrument surfaces can harbor bacteria and compromise sterilization. Damage to hard-to-clean regions, such as serrations, is especially problematic as it can be missed. Lighted magnification can be employed to make the identification of defects easier. Instruments with significant surface damage should be removed from service.

Implementing a maintenance schedule

A structured maintenance schedule enables consistent care of surgical instruments. Surgical tool maintenance can involve daily, weekly, monthly, quarterly, or yearly checks. Each maintenance should be accompanied by a detailed record specifying what was done.

Daily or weekly checks include point-of-use cleaning, proper instrument sorting, and visual inspections, while more thorough inspections, equipment calibration, and staff training sessions can be performed monthly or quarterly. A complete review of maintenance protocols, updating of policies based on new guidelines or research, and consideration of instrument replacement should be conducted annually.

A maintenance schedule improves patient safety and contributes to more efficient and cost-effective surgical procedures.