The choice of devices used during medical procedures affects imaging quality, especially when the devices block the image. Using certain materials might also increase the radiation dose to the patient, which naturally isn’t a good thing. And using some materials on magnetic resonance imaging (MRI) could be dangerous.

Understanding the physical and chemical properties of medical device materials is a key factor that can give you more successful and useful imaging.

This means it’s important to consider medical device material properties while planning interventional, surgical, and other medical procedures.

The article digs into how various device materials can interfere (or not interfere) with imaging and radiology in general. This will guide your decision and procedural planning. Some newer materials even offer cost benefits doctors may not be aware of.

How do device materials affect x-rays & imaging?

Conventional x-rays

In medical imaging, x-rays are used to assess the human body’s structure. X-rays are waves that can pass through human tissues. Various tissues have different densities. They attenuate x-rays at different degrees.

Device materials also differ in density and atomic composition. Thus, they attenuate x-rays at different levels. Materials that have higher attenuation coefficients (in other words, they can weaker the beam strength) tend to obscure other tissues to a greater degree.

Intraoperative imaging is often used to guide medical interventions. Obscuring visual fields of imaging studies with certain types of medical device materials is sometimes a problem.

Computed tomography (CT)

Some materials can induce artifacts on CT scans. This makes it hard to interpret. At a basic level, this is why hairpins and various types of jewelry must be removed during CT scans.

The need to repeat studies leads to higher radiation doses, which can be harmful.

The need to remove or relocate medical devices can be undesirable and time-consuming. Implantable and wearable medical devices can all create problems with CT. According to the U.S. FDA, these include:

- Insulin pumps

- Neurostimulators

- Pacemakers and defibrillators

Magnetic resonance imaging (MRI)

MRI-guided interventions are becoming a popular means of surgery.

According to this study, these procedures have many advantages over traditional x-ray-based methods. But MRIs work under strong magnetic fields. Therefore, all materials on and in the patient, and all medical device materials have to be MRI-friendly.

This is why patients are asked to remove watches, jewelry, hearing aids, and not bring electronic devices such as mobile phones into the MRI room.

Materials that move under strong magnetic fields or heat up while interacting with radiofrequency pulses are a potential hazard. These include nickel alloys and many stainless steel-based materials.

Indeed many conventional medical devices are made from such steel, and that has to be considered in MRI.

Ultrasound

Properties of medical device materials should also be noted during ultrasound-guided procedures. Metals and air completely reflect ultrasound waves. Other materials transmit them at different degrees.

The material’s appearance on ultrasound largely depends on its acoustic impedance. Metal does commonly show up on ultrasound, and even wood and glass can be seen. If they are foreign objects for removal, that’s good. If they’re instruments obstructing vision, then that’s is less desirable.

Metals (steel, titanium, etc.) and imaging

Metals and alloys such as stainless steel, titanium, nickel, cobalt, niobium, zirconium, aluminum, copper, tungsten, and tantalum are frequently used in medical devices.

This owes to their durability, strength, electrical conductivity, and long life. Their use dates back many centuries.

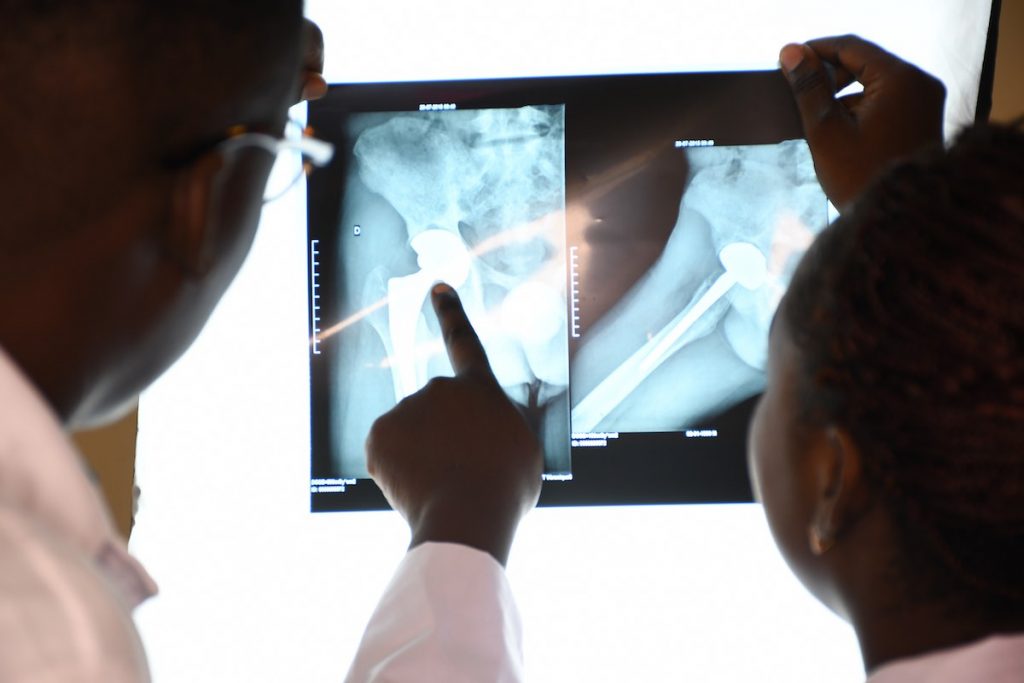

Metals are used in surgical instruments, bone implants, vascular stents, etc.

Dense metals with a higher atomic number attenuate x-rays more than lower-atomic-number metals. For example, the atomic number of iron is 26, while that of aluminum is 13. The mass attenuation coefficient of iron is higher than that of aluminum. The atomic number of calcium is 20.

Most metals attenuate x-rays at a significantly higher level than do human tissues. This makes it hard to distinguish between other overlaying structures. Metals appear as completely white structures on conventional x-rays. Other structures are differentiated in shades of gray.

X-ray detectors sum up attenuation coefficients of every structure between the x-ray source and detector. High-attenuating metals obscure the structures nearby. For example, you can’t differentiate normal and pathologic structures from nearby metallic jewelry. As this study suggests, metallic jewelry and piercings should be removed before taking x-rays. This will reduce radiation dose and improve image quality.

Metals also induce beam-hardening artifacts on CT scans. The object’s edges appear brighter than its central part, despite the same density. Metallic artifacts can obscure pathologic or normal tissues, leading to uncertainty for physicians.

Metallic devices, being radiopaque, are not always undesirable. Yet sometimes their visibility is helpful. The case of guide catheters and several targeting devices is a clear example of this. With these, the metal helps the doctor locate vessels and get oriented. They can also be used to mark structures not readily seen with x-rays.

Ferromagnetic metals, such as iron, nickel, and cobalt, are attracted by powerful magnetic fields used in MRI. Metallic objects start to move with great force. This can cause harm to both the patient and the scanner.

Some metals, such as aluminum and copper, are not attracted by magnets. However, they might heat up while imaging. Because of this, medical devices should be tested before they’re used during MRI.

Metals appear dark on MRI studies as they produce no signal. As discussed in this study, this can lead to significant artifacts.

Metals reflect ultrasound waves. Their reflective property is used in ultrasound-guided medical interventions. The reflection of sound waves by metal lets the medical professional visualize the metallic needle. When you observe the contour, it’s easier to guide it toward the desired location.

With metal as a very standard material in surgical instruments, care needs to be taken. But, as mentioned, the visibility of metals can also be a benefit in certain cases.

Plastics (polycarbonate, polypropylene, etc.) and imaging

Medical-grade plastics have diverse medical applications thanks to factors like durability, low cost, and lightweight.

Polycarbonates are known for their high-impact and temperature-resistant properties. This has led to their wide use in medical lenses and surgical instruments.

Polypropylene is durable and resistant to steam sterilization, so it’s widely used in surgical dressing and single-use medical equipment.

Polyethylene is common in medical implants because it’s resistant to impact and chemicals.

Because of their relatively low density, plastics normally appear as radiolucent structures on x-rays and interfere with imaging only to a small degree. Much less than metal.

Surgical retractors are a prime example of where plastics are beneficial with regard to imaging.

While using metallic surgical retractors, those reading the images will see radio-opaque shadows on the x-rays. This can obstruct the vision of the body structure the physician or radiographer is trying to see. Retractors can be repositioned or removed, but this takes time and may be inconvenient. Lighting also needs to be repositioned.

X-rays can also be angled in a way that won’t interfere with the desired field of view. But this requires an increased radiation dose to the patient.

Plastic surgical retractors will cut down your time. You won’t have to reposition them, and you’ll decrease the radiation dose (or keep it from needing to be increased).

In the same way, you can avoid inducing metallic artifacts on CT. Plastic materials don’t induce any kind of artifacts on this modality. The same can be said about MRI. Plastics are safe to use on MRIs since they don’t move under the magnetic field. They also don’t heat up under radiofrequency pulses.

Some plastic surgical retractors can be MRI-proof. Thus, you can perform intraprocedural imaging without wasting time on removing them.

Now, there are exceptions, such as if the surgeon needs a large-sized metal retractor to hold open the field of view. Some plastics can’t match that sheer power. However, in many surgeries, such as breast reconstruction and thoracic surgery, handheld plastic retractors are optimal for their maneuverability and their minimal obstruction both in the line of sight and on imaging.

Other materials and medical imaging

Apart from metals and plastics, several materials such as glass, silicon, ceramics, and textiles are used in medical devices. Like metals and plastics, their properties in imaging studies depend on their chemical structure and physical qualities.

Glass

Glass is used in optics. Glass can shield the organs of the patient, and shield the physician while performing procedures under x-ray guidance. For example, physicians widely use x-ray protective glasses to prevent eye damage.

Several types of glass transmit light, but not x-rays. Because of this, as summarized in this article, they are used as window materials in x-ray rooms.

Glass materials appear as radiopaque structures on x-rays and are easy to spot. However, glasses differ in composition and precautions should be made before using glass materials in MRI-guided interventions.

Silicone

Silicone is a chemically inert, biocompatible, hypoallergic, and stable material. Because of its properties, it’s commonly used in medical devices such as catheters and implants.

On x-rays, silicone appears radiolucent. This makes it hard to differentiate it from soft tissues. However, it can be differentiated on CTs and MRIs.

And a few more

Ceramics are widely used in dentistry and orthopedics/traumatology. In these fields, they are mainly used as bone implants. Some devices, such as pacemakers, also require ceramic materials. This owes to their electrically insulating properties. Ceramics appear radiopaque on x-rays and CTs.

Most of the textiles used in medical applications (e.g., artificial ligaments, vascular grafts, sutures) are radiolucent. But some are intentionally made radiopaque for better visualization on imaging.

Article medically reviewed by Shota Kuprava, MD.

—

To learn more about the advantages of plastic medical devices such as the koplight™ surgical light retractor, contact us at Yasui or download a brochure.